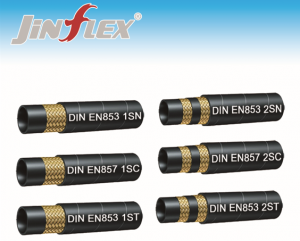

In the transmission stage of industrial fluids, steel wire wound hoses and steel wire braided hoses are like a pair of “twin flowers”. Although they look similar, they each have their own merits. Today, let us explore the unique features of these two in depth to provide you with clearer guidance when making your choice.

1. The beauty of structure: the art of winding and weaving

The steel wire wraps around the hose, and the inner wire wraps around the hose wall gracefully like a dancer, forming a strong barrier. This structure enables the hose to perform stably in high-pressure environments and ensure unobstructed fluid transmission. The steel wire braided hose shows another kind of artistic charm. The steel wires inside it are intertwined like warp and weft threads, weaving a fine and tough network. This network not only improves the wear resistance and tensile strength of the hose, but also gives it unparalleled softness and flexibility.

2. The charm of performance: each has its own strengths and characteristics

Steel wire wound hose is the best in terms of pressure resistance. It is like a tough warrior and can easily cope with the challenges of high pressure, high temperature and high flow. The steel wire braided hose has won praise for its excellent wear resistance and softness. It is like an elegant dancer, showing amazing adaptability and stability in complex and changing working conditions.

3. The dance of application scenarios: dance according to needs, and each takes the lead.

In terms of application scenarios, steel wire wound hoses and steel wire braided hoses each show their unique charm. The former is more suitable for industrial environments that need to withstand the impact of high pressure, high temperature, and high flow, such as petroleum, chemical, metallurgy and other industries; while the latter, with its excellent softness and wear resistance, is used in mechanical equipment that requires frequent bending and vibration. Automobile manufacturing, shipbuilding and other fields are shining brightly.

4. Wisdom of choice: adapt to local conditions and tailor things to your needs

When choosing these two hoses, we need to fully consider the actual application scenarios and specific needs. If you need a hose that can withstand high pressure, high temperature, and high flow, then steel wire wound hose will be your ideal choice; and if you pay more attention to the softness, wear resistance, and vibration resistance of the hose, then Steel braided hose is undoubtedly better suited to your needs.