Hydraulic hoses and four-layer steel wire wound hoses are both indispensable fluid transmission components in the industrial field, but they have obvious differences in their scope of application.

Hydraulic hose, as a versatile conveying tool, is mainly used in various engineering construction, lifting and transportation, metallurgical forging, mining equipment, ships, injection molding machinery, agricultural machinery, machine tools and various mechanization and automation systems. Its design is flexible and can adapt to the transmission needs of a variety of liquids and gases, including but not limited to hydraulic oil, fuel oil, lubricating oil, water, air, etc. In addition, hydraulic hoses can also work in a wide temperature range, ranging from -40°C to +100°C, showing their good adaptability.

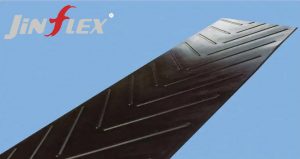

The four-layer steel wire wound hose, with its special structure and materials, focuses on more harsh industrial environments. Its four-layer steel wire winding structure gives the hose extremely strong pressure resistance and wear resistance, making it an ideal choice for high-pressure, high-temperature, and high-wear environments. This kind of hose is especially suitable for petroleum, chemical, mining and other industries. It can easily cope with various complex working conditions and ensure smooth and safe fluid transmission. In addition, the four-layer steel wire wound hose also adopts high-quality rubber material and steel wire wound structure, which can effectively resist the corrosion and high temperature of the medium, further broadening its scope of application.

To sum up, hydraulic hoses and four-layer steel wire wound hoses each have their own emphasis on the scope of application. Hydraulic hoses are popular for their versatility and adaptability; while four-layer steel wire wound hoses focus on more stringent industrial environments with their special structures and materials, providing more reliable products for specific industries. Fluid transfer solutions.