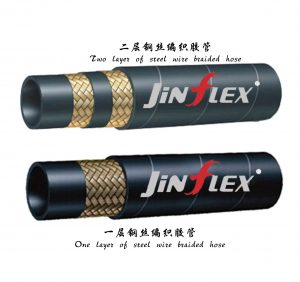

In the vast field of industrial materials, steel wire braided hose has become an indispensable part of many industries with its unique structure and excellent performance. Especially under harsh working conditions such as high pressure, corrosion resistance, and wear resistance, steel wire braided hoses have won wide recognition in the market with their outstanding performance. But did you know that steel wire braided hoses also have one layer and two layers? Today, let us uncover the mysteries of the two and explore the differences and mysteries between them.

1. Differences in structure: the difference between the first floor and the second floor

One layer of steel wire braided hose, as the name suggests, its structure mainly consists of an inner tube, a layer of steel wire braided layer and an outer tube. This structure is simple and efficient, and the steel wire layer directly provides support and protection for the inner tube, allowing it to withstand a certain amount of pressure and impact. The two-layer steel wire braided hose adds a layer of steel wire braid between the inner tube and the outer tube to form a stronger protection system. This double-layer design not only improves the hose’s pressure resistance and wear resistance, but also increases its overall stability and service life.

2. Differences in performance: each has its own merits

In terms of performance, one-layer steel wire braided hose and two-layer steel wire braided hose each have their own advantages. Due to its light structure and flexible bending performance, a layer of steel wire braided hose has obvious advantages in situations where frequent bending and movement are required. At the same time, its lower manufacturing cost also makes it the first choice for some cost-sensitive projects. The two-layer steel wire braided hose, with its higher pressure resistance and wear resistance, shows excellent performance under severe working conditions such as high pressure and high wear. In addition, its longer service life and more stable performance also make it an ideal choice for some long-term, continuous work projects.

3. Differences in application scenarios: adapting measures to local conditions

In terms of application scenarios, one-layer steel wire braided hose and two-layer steel wire braided hose also have their own scope of application. One-layer steel wire braided hose is widely used in low-pressure and low-wear applications in petroleum, chemical, agriculture and other industries because of its lightness and flexibility. The two-layer steel wire braided hose has become the first choice under severe working conditions such as high pressure and high wear due to its excellent pressure resistance and wear resistance. Especially in the petroleum, chemical, shipbuilding and other industries, the two-layer steel wire braided hose has shown excellent performance when transporting oil, water, gas, liquid and other fluids.

4. The way to choose: tailor-made

When choosing steel wire braided hose, we need to tailor it according to the specific use environment and needs. For low-pressure, low-wear situations, one layer of steel wire braided hose is enough to meet the needs; for high pressure, high wear and other severe working conditions, two layers of steel wire braided hose can provide more reliable and stable protection. At the same time, we also need to consider the material, connection method, length and other factors of the hose to ensure that it can perform optimally in actual applications.

In short, one-layer steel wire braided hose and two-layer steel wire braided hose each have their own characteristics and advantages, and they need to be weighed according to specific needs when choosing. On the way to explore the world of hoses, we need to continue to learn and understand the characteristics and performance of various products in order to make more informed choices in practical applications.