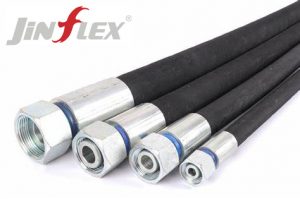

Rubber hose joints are an important pipeline connector used to connect hoses in pipeline systems, which can effectively ensure the stability and stability of liquid and gas transportation. It can connect hoses of different types, specifications and uses, and has the advantages of easy installation, strong sealing and high reliability.

However, rubber hose joints are prone to falling off and leaking during use. Do you know why?

Substandard material quality, unreasonable design, irregular installation, improper use, etc. all have an impact on hose joints.

But now our company is a high-tech research institute specializing in the research of rubber hoses and hose joints. We use

1. High-quality raw materials: Use high-quality rubber materials from internationally renowned brands to ensure that the corrosion resistance, wear resistance and strength of the joints are in the best state.

2. Exquisite production technology: Through precise mold design and strict process control, the dimensional accuracy and sealing performance of the joints are ensured.

3. Strict quality inspection: We conduct strict quality inspections on every production link, including material inspection, dimensional measurement, sealing performance testing, etc., to ensure that every joint meets quality standards.

4. Reassuring quality service: Our company has always attached great importance to after-sales service. We have a professional after-sales service team that can provide customers with timely and professional technical support and solutions. Whether you encounter problems during product installation, use or maintenance, customers can contact us at any time and we will serve you wholeheartedly. At the same time, we also provide regular return visits and inspection services to ensure that customers receive comprehensive protection and support during the use of our products.https://www.jinflexhome.com