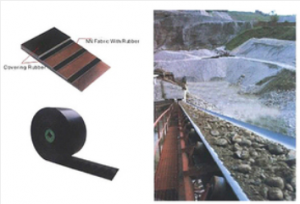

Applications:

Used in coal, ore, port, electric power, metallurgy, chemical, food and building industries, suitable for long distance and heavy load transportation of materials.

Varieties:

According to the difference of tensile layer materials, layered textile conveyor belt can be divided into: Cotton canvas (CC) conveyor belt, Nylon (NN) conveyor belt, Polyester (EP) conveyor belt.

Cotton canvas (CC) conveyor belt

A trational conveyor belt, suitable for medium and short-distance transportation of materials.

Nylon (NN) conveyor belt

NN conveyor belt has good elasticity, high strength, good impact resistance, good flexibility, good groove-fromaed and small elongation, suitable for conveying materials under the conditions of medium and long-distance, heavy load and high-speed.

Polyester (EP) conveyor belt

EP conveyor belt has high modulus, small elongation, good heat-resitance and good impact resitance, suitable for conveying materials under the conditios of medium and long-distance, heavy loading and high-speed.

Technical date for Multi-ply fabric conveyor belt

|

Belt type |

Fabric type |

Single fabric strength(N/mm) |

Single fabric thickness(mm) |

Rubbercover thickness (mm) |

Ply |

Belt width range(mm) |

Belt length mm/roll |

|

|

Top rubber cover |

Bottom rubber cover |

|||||||

|

CC |

CC-56 |

56 |

1.10 |

3.0/4.5/6.0 |

1.5/3.0 |

3-12 |

500-2200 |

100-1000 |

|

NN |

NN100 |

100 |

0.70 |

2-10 |

||||

|

NN150 |

150 |

0.75 |

2-6 |

|||||

|

NN200 |

200 |

0.90 |

||||||

|

NN250 |

250 |

1.15 |

||||||

|

NN300 |

300 |

1.25 |

||||||

|

NN400 |

400 |

1.50 |

||||||

|

EP |

EP100 |

100 |

0.75 |

2-10 |

||||

|

EP150 |

150 |

0.85 |

2-6 |

|||||

|

EP200 |

200 |

1.00 |

||||||

|

EP250 |

250 |

1.20 |

||||||

|

EP300 |

300 |

1.35 |

||||||

|

EP350 |

350 |

1.50 |

||||||

|

EP400 |

400 |

1.65 |

||||||

According to the difference of rubber cover, layered textile conveyor belt can be divided into General type, Heat-reistant type, Abrasion-resitant type, Heating-grind resistant type, General fire-resistant type, Static electric conduction type, Acid and alkali-resistant type, Oil-resistant type and Food type etc.

|

Varieties |

Characteristics and Applications |

|

General type |

used for conveying materials in general fields, suitable for power, granular and bulk materials |

|

Oil-resistant type |

with oil-resistant performance, and used for conveying oil-bearing materials |

|

Acid and alkali resistant type |

used for conveying acid and alkali materials with4-10 PH value, and can resist such materials as certain concertration hydrochloric acid, sulfuric acid, nitric acid and weak base etc |

|

Heat-resistant type |

It is divided intoT1 type which temp resistance is not more than 100centigrade and T2 type which temp resistance is not mre than 125 entigrade |

|

High temp resistant type |

T2 type temp resistant is not more than 150 centigrade and high temp type is not more than 180cenitgrade, they are suitbale for conveying metallurgy, coking, buolding materials and foundry industry sinter product, cement, plastic and all kinds of high temp materials. |

|

Fire resistant type |

this conveyor belt surface has fire resistant performance, can put our a fire momently, suitable fore the conveying palce which need fire resitant. |

|

Cold resistant type |

this conveyor belt surface has cold resitant perfromance, can be used under the condition which temp is above-40 centigrade, suitbale for conveying materials in the ocld and open air areas. |

|

Abrasion resistant type |

this conveyor belt surface has such performance which can resit impact and resit abrasion of materials edge angle, suitbale for conveying hard sharp edge angle materials. |