Hydraulic hoses are usually composed of inner tubes, reinforcement layers, and outer protective layers, which have the ability to withstand high-pressure fluids. The following are typical hydraulic hose structures:

1. Inner tube (inner rubber layer): The inner tube is the innermost layer made of synthetic rubber material with good oil resistance, usually reinforced with polyester or chloroprene rubber. The main function of the inner tube is to come into contact with the fluid medium, and it also needs to have characteristics of chemical corrosion resistance and wear resistance.

2. Enhancement layer: The enhancement layer is usually located outside the inner tube to increase the pressure resistance of the hose. The reinforcement layer can use multiple layers of materials, such as high-strength synthetic fibers, steel wire woven fabrics, or steel wire spiral winding. The reinforcement layer can withstand high pressure, allowing the hydraulic hose to maintain stability during high-pressure liquid flow.

3. Outer protective layer (outer adhesive layer): The outer protective layer is located outside the reinforcement layer and is used to protect the hose from external physical damage and environmental influences. The outer protective layer is usually made of materials such as synthetic rubber, polyethylene, or polyurethane, and has characteristics such as wear resistance, UV resistance, and weather resistance.

According to different application scenarios and requirements, hydraulic hoses may also add some other special layers or coatings, such as high-temperature resistant layer, conductive layer, flame retardant layer, etc., to adapt to special working conditions.

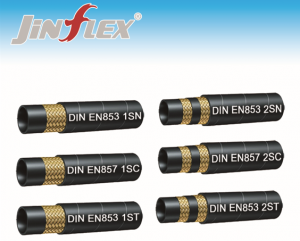

Zaozhuang Jinfulex Rubber Technology Co., Ltd. reminds everyone that the structural design and material selection of hydraulic hoses are crucial. Reasonable design and selection should be based on actual working pressure, environmental conditions, medium characteristics, and fluid transmission requirements to ensure the safety, reliability, and service life of hydraulic hoses. Before using hydraulic hoses, it is best to refer to relevant standards, technical specifications, and product information provided by suppliers to ensure that the structure and performance of the hoses meet the required working conditions and requirements.